PR20 Ultrasonic Pulse Generator and Receiver

Key words:

Product Classification:

- Product Features

- Applications

- Technical Parameter

- Standard Configuration

-

Product Advantages

Maximum bandwidth 20MHz

Internal trigger of repetition frequency:

8 adjustable levels (4Hz-2KHz)

Pulse width adjustable from 1 to 40 times (1 time is approximately 28ns)

8 selectable transmission voltages, up to 400V

Product Advantages

Multi-level adjustable damping value

Supports one-transmitter-one-receiver modeand pulse echo mode

60dB receiving gain rangeReplaces traditional pulse generation and reception devices

PR20 Pulse Generator and Receiver

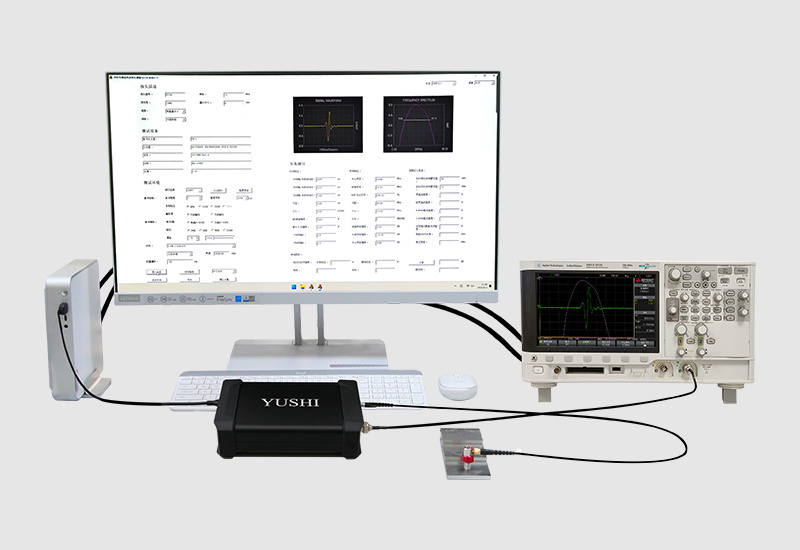

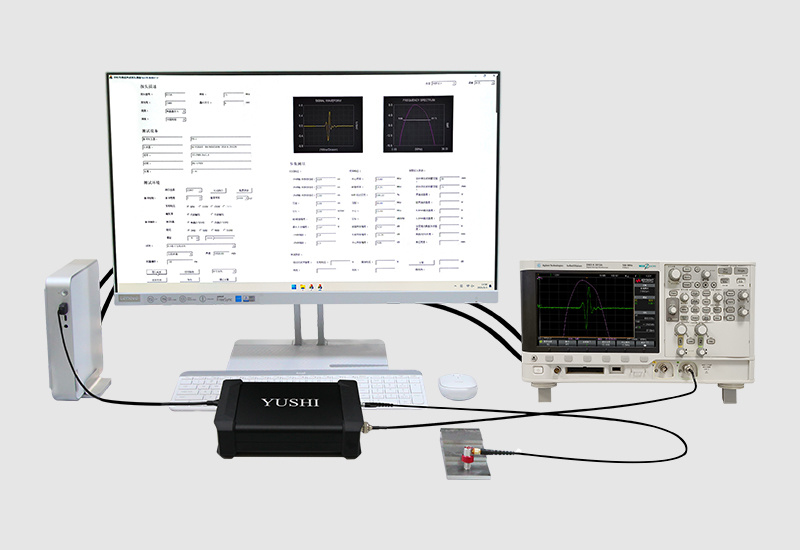

Developed and produced by Shenyang Yushi Pioneer, the PR20 is a high-performance ultrasonic pulse generator and receiver controlled by a computer. The instrument connects to a computer and an oscilloscope and can assist in ultrasonic flaw detection, thickness measurement, and ultrasonic transducer testing. It has a wide range of Applications in non-destructive testing and material analysis.

Host Specification

External Dimensions

18.4cm*12.6cm*5cm

Weight

542g

Operating Temperature

0-55℃

Testing Platform

Building an ideal testing platform

The pulse generator and receiver connects to a computer and an oscilloscope. Using the instrument's built-in control software, ultrasonic flaw detection, material thickness measurement, probe performance analysis, and material property analysis

can be performed.

In addition, with specialized ultrasonic transducer testing software, an ultrasonic transducer testing system can be built.

-

Application of the testing platform in fields such as non-destructive testing

Probe Performance Testing

In the ultrasonic testing process, the probe plays a very important role. The quality of the probe directly affects the accuracy and reliability of the flaw detection results. The testing platform can measure and analyze the time-domain and frequency-domain responses of the echo signal from the probe in the working state.

Material Analysis

Using the ultrasonic pulse reflection principle, the mechanical properties and quality of the material are evaluated by measuring the speed of ultrasonic waves propagating in the material. It is widely used in the field of materials engineering, especially in material evaluation and quality control.

Ultrasonic Flaw Detection and Thickness Measurement

Using the ultrasonic pulse reflection principle, the waveform is measured and analyzed. Flaw detection is used to determine the presence, size, and location of defects. Thickness measurement can obtain the workpiece thickness through the known material sound velocity and the time interval between two echoes.

-

Control Parameters

Control Parameters

Range

Step

Launch Area

Launch Voltage

60V, 110V, 150V, 200V, 250V, 300V, 350V, 400V

Selection

Pulse Width

1~40 (1x is approximately 28ns)

1x

Repetition Rate (Internal Trigger)

4Hz, 8Hz, 16Hz, 20Hz, 100Hz, 500Hz, 1kHz, 2kHz

Selection

Trigger Source

Internal Trigger, External Trigger

Selection

Receiving Area

Single/Dual Crystal

Single Crystal (1T/1R), Dual Crystal (1T/2R)

Selection

Damping

34Ω, 50Ω, 90Ω, 510Ω

Selection

Gain

0~60dB

1dB

Technical Parameters

Pulse Type

Negative Square Wave Pulse

Rise Time

Generally between 2.0-7.5ns, up to 20ns or more with 510Ω damping

Fall Time

Generally around 2.8ns

Pulse Width

1x pulse width is approximately 28ns

Bandwidth

0.5-20MHz

Excitation Mode

Pulse-Echo (P-E), Transmission (T-T)

Repetition Rate

Internal trigger: 4Hz-2kHz; External trigger: 0-20kHz

External Trigger

Rising edge trigger; Trigger voltage: 3.3V;

-

Host Specification

External Size

18.4cm*12.6cm*5cm

Operating Temperature

0-55℃

Weight

542g

Standard Configuration

Host PR20

1

Connecting Cable Q9-Q9

2

Communication USB Drive

1

USB Type-C / Data Cable

1

Control Software (Located in the USB drive)

1

Related Accessories

Product Inquiry

Official Account

Contact Us

Address: No.81 -43 Puhe Road, Shenbei New District, Shenyang City, Liaoning Province