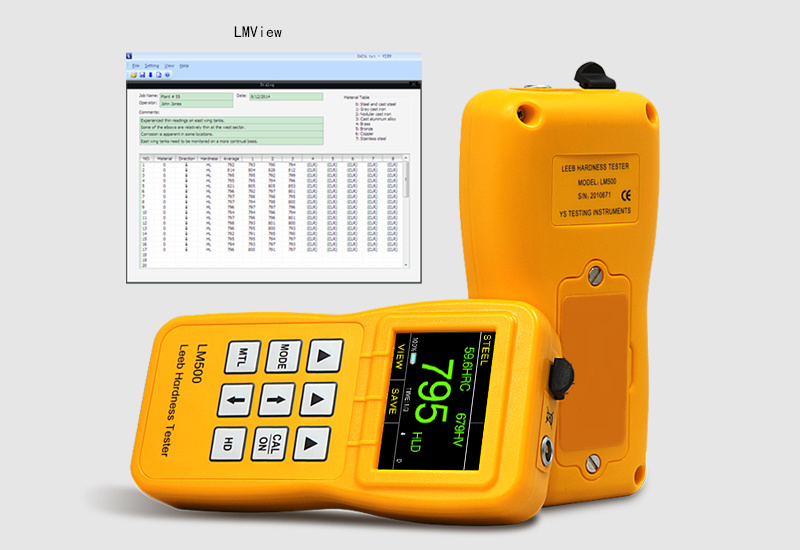

LM500 Leeb Hardness Tester

Key words:

Product Classification:

- Product Features

- Applications

- Technical Parameter

- Standard Configuration

-

Product Features

Colorful large screen, clear and bright

Stable readings, accurate measurements

Eye-catching colorful large number display interface

Functional Features

Six Hardness Measurement Scales

Rockwell C, Rockwell B, Vickers, Brinell, Shore, Leeb, and tensile strength

Measurement Directions

Vertically downward, diagonally downward, horizontal, diagonally upward, vertically upward (can automatically identify direction)Three hardness scales displayed on the same screen

Brinell, Rockwell, and Vickers three scales do not need to switch, displayed on one screen

Hardness Curve

The hardness curve consists of the most recent 30 impact values

Facilitates observation of the uniformity of the measured objectImpact Device

D-type: Universal impact device, suitable for measuring various conventional workpieces

C-type: Measures small, thin components and surface hardened layers

DC-type: Measures inside holes or cylindrical tubes

G-type: Measures large, heavy, and relatively rough castings and forgings

DL-type: Measures narrow grooves or holes

Communication Software

Standard LMView software

Can store 11,000 sets of hardness values -

LM500 - Measured Application

-

LM500 - Technical Parameters

Display Color HD 2.4 inch QVGA (320×240 pixel) IPS screen Measurement Method Leeb Hardness Measurement Method Measurement Range HLD (200-960) HRC(19.8-68.5) HRB(13.5-100) HB(30-651) HV (80-976) HS (26.4-99.5) ob (375-2639) Hardness Standard Leeb HL, Brinell HB, Rockwell HRB, Rockwell HRC, Vickers HV, Shore HS, Strength ob Impact Device Standard D, optional C/G/DC/DL Display Error Error less than ±6HLD (HLD=800), repeatability error less than 6HLD (when HLD=800) Test Direction Supports vertical down, diagonal down, horizontal, diagonal up, vertical up Applicable Materials Steel and cast steel, stainless steel, gray cast iron, ductile iron, cast aluminum alloy, copper-zinc alloy, copper-tin alloy, pure copper, alloy tool steel, forged steel Resolution 1HL, 1HV, 1HB, 0.1HRB, 0.1HRC, 0.1HS Working Language Chinese, English, French, Japanese, Italian and other languages available. Data Storage 200 files, 11,000 groups (each group contains 1-8 hardness values and 1 average value) Communication Interface USB interface Application Software Comes with LMView software for managing, archiving, printing measurement data, etc. Working Power Supply Two 1.5V AA batteries Working Temperature -10 to +50℃ Instrument Size 153mm×76mm×37mm (H×W×D) Weight 242g including battery Standard Complies with GB/T 17394-1998, ASTM A956 standards -

LM500 - Standard Configuration

● Hardness Tester Main Unit ● Nylon Brush ● Probe (D) ● No. 5 Alkaline Battery ● Hardness Block ● Product Packaging Box ● Communication CD ● User Manual ● USB Communication Cable ● Certificate of Conformity ● Small Support Ring ● Warranty Card

Related Accessories

Product Inquiry

Official Account

Contact Us

Address: No.81 -43 Puhe Road, Shenbei New District, Shenyang City, Liaoning Province