Bimetallic composite plate material thickness measurement

Product Sample

· Upper layer 20# steel with a cladding of 304 stainless steel bimetallic composite material

The explosive welding method is used to achieve bonding between the surfaces of the two metals. The cladding is a corrosion-resistant layer.

The thickness of the 304 stainless steel is only about 3mm.

· Measurement Difficulties

The acoustic impedance of 20# steel and 304 stainless steel is similar, although interface reflection waves can be observed,

the reflection waves are weak, and the interface reflection characteristics at the measurement point are not obvious.

Measurement Principle

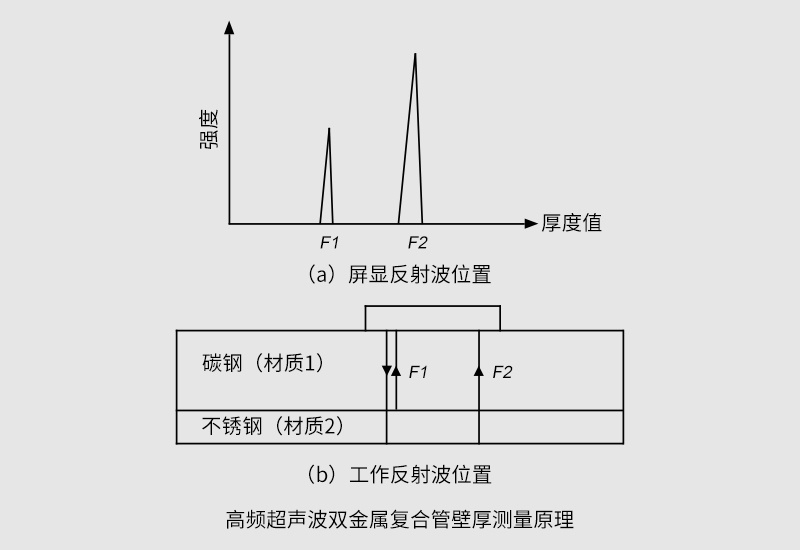

· High-Frequency Ultrasonic Measurement Method

With the increase in the incident frequency of the pulsed ultrasonic waves, the wavelength of the ultrasonic waves shortens, and in the case of coarse corrosion-resistant alloys combined with the base carbon steel,the diffracted waves decrease, while the reflected waves increase,making the echoes at the anisotropic composite interface more pronounced, thus solving the sensitivity issue of measuring the wall thickness of bimetallic composite pipe

High-Frequency Probe Selection

· Standard Delay Line Probe D15A6

Using a high-frequency ultrasonic thickness gauge allows for precise measurement of the thickness of the base layer and cladding of metallurgically bonded bimetallic composite pipes,with a measurement accuracy of ±0.05mm,effectively solving the problem of accurately measuring the thickness of the base layer and cladding of metallurgical composite pipes.

Actual Measurement Results

· Probe Type

15MHz Delay Line Probe

· Measurement Mode

Interface Wave - Echo Method

Official Account

Contact Us

Address: No.81 -43 Puhe Road, Shenbei New District, Shenyang City, Liaoning Province